Proud to be British - Kingfisher Lubrication join Made in Britain

As a manufacturer within the UK, we are proud to announce we have been awarded the Made in Britain® Trademark. Being recognised as the sole manufacturer of grease fittings within Britain is something we take pride in and embody as part of our everyday communications in both national and international markets.

UK manufacturing and engineering continues to be one of the highest growing industries. As a British manufacturer, we are pleased to be a part of this push for growth and want to be a standard bearer within Lubrication manufacturing in the UK.

What does being a British manufacturer mean?

Kingfisher Lubrication are based in Leeds, West Yorkshire. In Leeds and across the UK, there are superb manufacturing companies who all share this badge of being Made in Britain. As one of their newest members, we are proud to be continuing this commitment and embodying being British as a wider part of our brand identity.

In international and local markets, being a British manufacturer holds value. Research from Barclays Corporate Banking shows that 39% of international consumers are more likely to purchase a product if it is British as it perceives quality. At Kingfisher, we pride ourselves on providing our customers industry-leading quality and the Made in Britain mark aims to promote quality manufacturing in the UK – making the membership a great representation for us as a business.

Driven by our values

When Kingfisher became an Employee Ownership Trust in 2020, collectively all our employees decided on a set of six core values to embody who we are and what we do. Two of the values decided by our staff were ‘British’ and ‘Quality’.

Being British is a major part of the company’s identity and history. Kingfisher have a 157-year long affinity with UK manufacturing and since establishment we have had a major presence as a recognised employer of local talent and supplier of high-quality products in Leeds and across the country.

In addition, within the local and international landscape of manufacturing, being a British manufacturer exudes a high-level of quality. ‘Quality’ was nominated as one of our company values as that’s what we do – our dedicated and highly proficient workforce take pride in consistently delivering the finest grease fittings and lubrication components the industry has to offer.

Therefore, with Made in Britain’s purpose being to promote quality manufacturing within Britain, we feel that the trademark fits perfectly with our company values. Learn more about our company values here.

March 13, 2024

Sustainability

Sustainable Innovations: Solar Panels

It has been a monumental few months at Kingfisher as far as innovation is concerned. In addition to the arrival of our brand-new Index MS22 machine, we have had solar panels installed in recent months.

As a manufacturing business in Leeds, our green and sustainability credentials are massively important to us and present a major opportunity to establish ourselves as a leader in sustainable manufacturing within our market. That is why we have taken steps, like installing solar panels, to reduce our carbon footprint and improve our energy efficiency by adopting renewable energy

What will Solar Panels provide for Kingfisher?

In partnership with Heatsource Direct, we were able to install a high-quality solar system which has been built to last. Not only have we future-proofed with a new major energy source for our business; we have taken advantage of the opportunity to reduce our carbon output by operating with renewable energy generation.

Longer-term – the solar panels will make our manufacturing processes more efficient and cost-effective with less non-renewable energy required to power our intensive line of manufacturing machinery. Eventually, this will enable us to pass on these reduced manufacturing costs to our loyal customers due to our reduced energy usage.

Helen Thornley, Financial Director at Kingfisher Lubrication, said: “We’re well aware of the need for the manufacturing industry to lower its carbon footprint and we have been working hard to bring down our emissions where we can, with solar energy high on our green wish list. So, to have completed this project and improve our sustainability credentials is really pleasing.”

This innovation would not have been possible without the support and expertise of the team at Heatsource Direct. If you would like to find out more about their offerings, you can visit their website here.

How much energy will we save?

In the peak summer months, when we experience the joys of the Great British summertime, we will be able to generate enough energy from the sun to power up to 30% of our manufacturing efforts. This is a major boost for us as a business, as we make a concerted effort to increase our efficiency and reduce our wastage within the way we manufacture our products. Not to forget, this has major cost-saving benefits with the astronomical rises of energy in recent months.

Sustainability at Kingfisher

We pride ourselves on adopting sustainable processes within our business. The need for sustainability within the manufacturing industry is paramount and our eventual goal is to be an industry leader in the adoption of green processes. We have already taken key major steps, like installing solar panels, on our journey to be a sustainable manufacturer but we are also aware of how much work there is left to do for us as a business and the industry as a whole.

Some of the other sustainable initiatives we have adopted to date include:

– Recycling up to 92% of our manufacturing waste

– Installation of energy-efficient LED lighting across our manufacturing and office spaces

– Innovation and streamlining of internal processes with the ultimate goal of being paper-free

You can find out more information about our commitment to sustainability on our environmental policy page here.

February 14, 2024

Innovation

Innovation at Kingfisher: Index MS22 Multi-Spindle CNC Lathe Machine

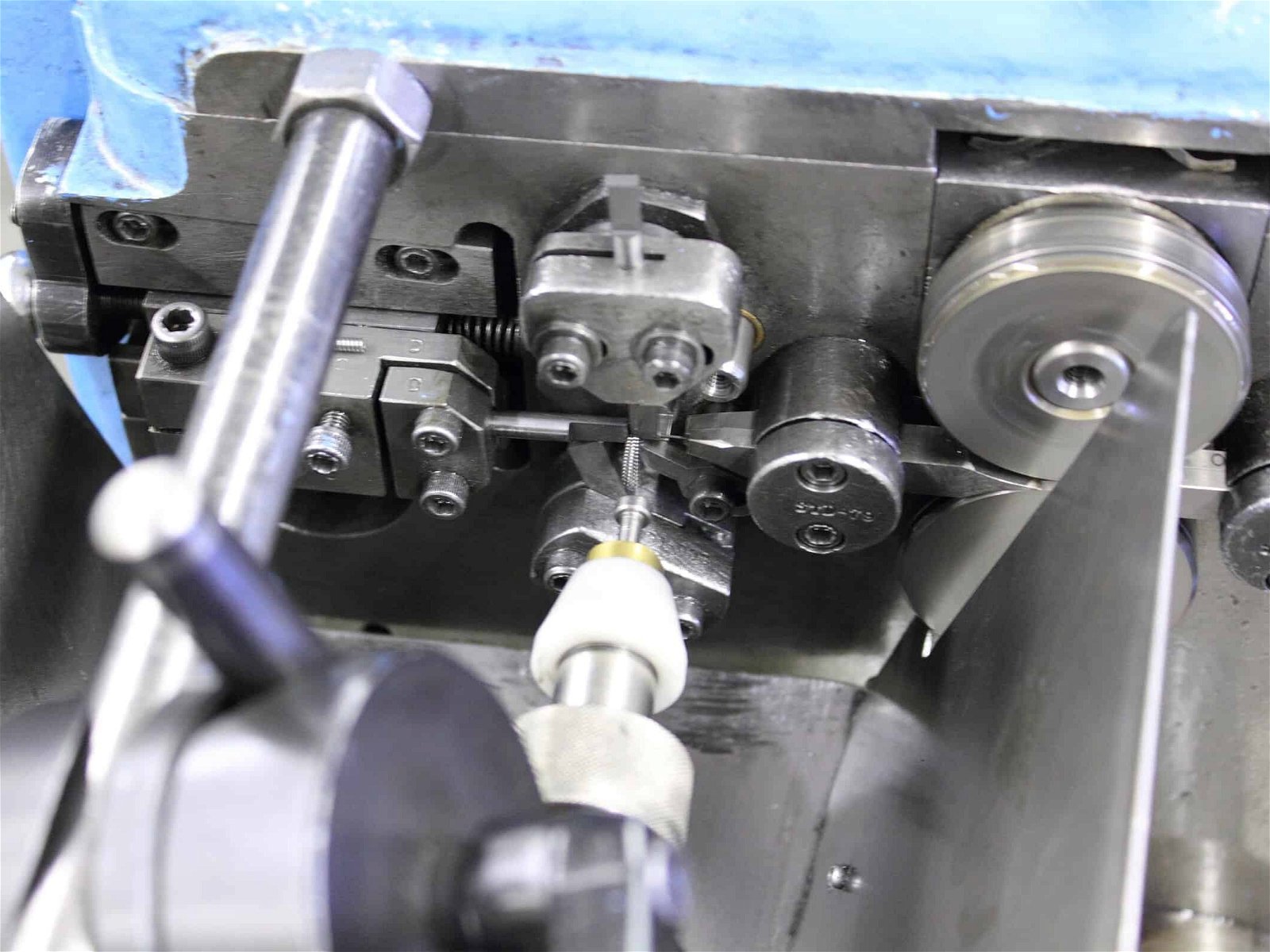

As a business, Kingfisher Lubrication strives to be an industry leader in the grease fittings industry with the highest quality processes and products available to our customers. With that in mind, we realise the importance of embodying innovation and the implementation of improvements to our manufacturing processes. As a result, we are proud to announce the investment of our latest innovation – the Index MS22 Multi-Spindle CNC Lathe Machine.

In partnership with Kingsbury, we are delighted that we have been able to achieve a huge milestone for the business. Despite this being a huge milestone at the end of one project, this is only the beginning of what will be an even more exciting scheme of innovation for the business with several new opportunities to be targeted and pursued.

Simon Dutton, Kingsbury, pictured with Chris Lemm, Works Director at Kingfisher, in front of the new machine.

What is an Index MS22 CNC Lathe Machine?

The Index MS22 Machine is a six-spindle full CNC production machine with multiple tooling options for high-volume precision components. The CNC machine is designed for optimised tooling set-up times. The ability to operate the machine using multiple tools and at various speeds enables a diverse range of products to be manufactured and materials to be machined in impressive time.

Why has Kingfisher chosen to invest in an Index MS22 CNC Lathe Machine?

The machine is a major investment for Kingfisher as a business. However, with our commitments to quality and manufacturing using the most innovative and efficient processes we believe that investment in innovation is vital to fulfilling our business values and continuous desire to be an industry leader in new and existing markets.

The new multi-spindle will enable us to streamline our manufacturing processes and increase the efficiency of our component output. Therefore, further reducing lead times and our ability to manufacture larger-scale jobs with our unwavering dedication to match the needs of customers and clients. Whilst we are proud of our position as one of the oldest manufacturers of grease fittings in the world, we are also excited about the new capabilities this machinery will bring to our manufacturing abilities.

The delivery of Kingfisher’s New Index MS22 Multi-Spindle CNC Lathe Machine

Managing Director, Lorraine Nugent, spoke about what this latest innovation means for Kingfisher Lubrication, “The Index MS22 CNC Lathe machine opens new doors for Kingfisher. With the potential for increased manufacturing capacity and to produce new products, we are optimistic about the opportunities that lie ahead for us as a business and our customers following this innovative investment.”

What does this innovation mean for new and existing customers?

At Kingfisher Lubrication, we are proud of our heritage. We have been manufacturing grease fittings for 80 years, and with this new investment will be able to increase our output and overall quality of our products, ensuring our customers are even happier with the products we provide.

In addition, this machinery makes Kingfisher an even more versatile manufacturer of precision metal components. With 157 years of experience dealing with the manufacturing of high-precision metal components, we are actively seeking new opportunities to form new partnerships and aid clients in their production. The Index MS22 enables us to partner our expertise with the latest technologies in the industry to deliver the demands of our customers to the highest level possible.

Does this sound like something that could benefit you and your business? Get in touch today to see how we can help you in the manufacture of grease fittings and other metal components. You can contact us here.

February 6, 2024

Insight

What is a Grease Nipple?

Understanding Grease Nipples: A Comprehensive Guide

Introduction

Grease nipples, also known as grease fittings or Zerk fittings, play a crucial role in machinery maintenance by ensuring that moving parts receive the lubrication they need for optimal performance. In this article, we will delve into what grease fittings are, their importance, and how they contribute to the longevity of mechanical components.

What Are Grease Nipples?

Grease fittings are small metal devices installed in various mechanical systems to facilitate the application of lubricants, typically grease, to moving parts. These fittings provide a point of access for injecting lubricants into components like bearings, joints, and other friction-prone areas. By regularly greasing these parts, friction and wear are minimised, ultimately extending the lifespan of the machinery.

Importance of Grease Nipples

The primary function of grease fittings is to prevent metal-to-metal contact and reduce friction within machinery. Friction is a major cause of wear and tear in moving parts, leading to increased maintenance costs and decreased efficiency. Grease nipples ensure that a consistent and adequate amount of lubricant is applied to critical areas, creating a protective barrier that minimises friction and heat build-up. In addition, this reduces the amount of energy that machines require to run because of reduced friction and heat build-up within mechanical systems.

Proper lubrication through grease fittings also helps in preventing corrosion, rust, and contamination of moving components. This is especially important in harsh environments or applications exposed to moisture and debris. By regularly applying grease through these fittings, machinery owners can significantly reduce the risk of premature component failure and costly repairs. Discover what can happen when you use a faulty or poor quality grease fitting here.

Conclusion

In conclusion, grease nipples are indispensable components in the realm of machinery maintenance and functionality. Regular and proper lubrication through these fittings is essential for preventing wear, reducing friction, and ensuring the smooth operation of mechanical systems. Therefore, reducing the energy required for machines to function at their required levels of performance. Implementing a proactive greasing schedule with the use of grease fittings can lead to increased efficiency, decreased downtime, and ultimately, significant cost savings in the long run. As a vital aspect of protective maintenance, grease nipples require attention during selection to keep the machinery running smoothly and reliably.

For high-quality grease fittings, consider Kingfisher Lubrication. Browse our website for a range of durable and reliable products designed to meet your machinery lubrication needs.

November 15, 2023

News

The Story Behind The Saints Row Mural

Leeds is home to many artistic and visual spectacles, including possessing its own art gallery. In 2022, Kingfisher Lubrication became home to one of the city’s newest and most eye-catching works of art as part of the launch of a brand new video game.

A target of Vandalism

The exterior wall of the Kingfisher Lubrication building, backing onto Sackville Street, was previously a target of vandalism. Covered in graffiti and creating an eyesore for passers-by of the Kingfisher premises, we believed that the wall could be put to good use for something creative that truly represented what we stand for as a business within the wider Leeds community.

The proposal dedicated for a mural alongside the launch of the new Saints Row relaunch in 2022 did just that.

Plaion / THQ / Deep Silver. | Image credit: Plaion / THQ / Deep Silver

The “Boss Factory” mural inspired by the launch of the 2022 reboot was created by street artist Captain Kris.

Leeds – “The Boss Factory”

Plaion, the game developer and creators of the Saints Row game which launched in 2022, commissioned some research to find out which city within the UK was the embodiment of entrepreneurialism among young people. The research targeted at 18 – 30-year-olds revealed that Leeds was the epitome of entrepreneurship as the most entrepreneurial city in the United Kingdom.

The free-world simulator, Saints Row, is all about being your own boss. Hence why the correlation between the most entrepreneurial city in the UK and the game made a perfect destination for such a mural. When approached about using the exterior wall of our site for the mural, we at Kingfisher jumped at the opportunity as we believe that the freedom to be creative and innovative as an entrepreneur correlate directly with our business values as an employee-ownership trust.

Plaion / THQ / Deep Silver. | Image credit: Plaion / THQ / Deep Silver

A new artistic addition to the UK's most entrepreneurial city

The mural, which a year on still sits on the side of our manufacturing premises, has become a mini tourist attraction within the Meanwood area of Leeds. Many people can be seen stopping to take a picture of the wall art.

Whilst the launch of Saints Row is now finished, we are still proud to have such an embodiment of our city's title as the "most-ambitious" city attached to our business. Want to learn more about Kingfisher Lubrication? You can view our story here.

October 19, 2023

Report on ¼ x 28 Special Taper Grease Fittings

Report on ¼ x 28 Special Taper Grease Fittings

Kingfisher obtained 3 competitors’ samples of ¼ x 28 special taper grease fittings. These fittings appear to have been cold forged (as opposed to machined) and as such have rounded corners on the hexagon and a concave ball check face.

As the corners of the hexagon were rounded and not formed properly, it was difficult to measure the hexagon dimensions. The rounded corners may prove detrimental when using a socket to screw in the fitting. Most sockets and spanners rely on the corner part of the hexagon to screw them in.

The threads are rolled (not cut) which produces a slight undercut at the top of the thread. The fittings supplied had a shank diameter of 0.248″-0.249″.

Picture showing concave ball check face, also there is a score mark on side of the head which appears to have been caused during manufacture as the plating is undamaged. The ball check face should be flat to reduce the build up of contaminants on this surface which may get introduced into the fitting during greasing.

Also of note is the yellow colour of the plating has rubbed off on exposed surfaces.

The fittings have been hardened to 85-88 HR15N, but the lip appears to have been subsequently softened to make it easier to fold over to retain the spring. (The end of the fitting is discouloured suggesting heat has been applied) This could also soften the first threads which could affect the fittings’ ability to start forming a thread in a hole.

The fittings were grease tested, the opening pressures were 60, 70 and 240psi which is a wide range indicating inconsistent manufacture and 60/70psi is rather low for a hydraulic fitting.

The fittings passed the leakage test specified in SAE J534.

When the fittings were high-pressure grease tested at 8,000psi (which is the pressure that Kingfisher test at) both springs collapsed. This is a critical failure.

The other fitting was high-pressure tested to 5,000psi as per SAE J534. The spring also collapsed.

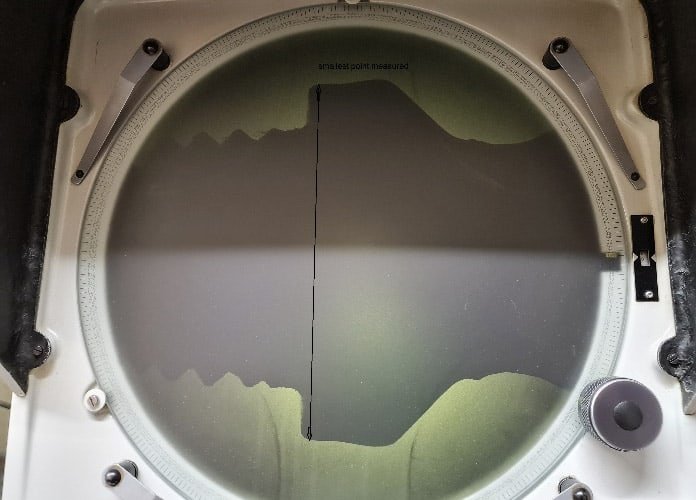

Picture of the grease fittings after high pressure testing showing the that the balls haven’t re-seated, the 2 fittings on the left were tested at 8000psi and the one on the right was tested at 5000psi.

Report on Imported Grease Fittings

Kingfishers' findings on Imported Grease Fittings

Samples were obtained of imported grease fittings which are being offered as a cheaper alternative to Kingfisher. These parts (1/8” x 28 BSP Straight) were examined and the following was found:-

- The parts were not hardened. They should be case hardened.

- Some of the threads were very slack in the 1/8×28 BSPF no/go gauge. This may lead to leakage around the threads.

- The flank angle of the thread was 60°-65° (it should be 55°)

- The shank length compared with DIN71412 was too short at 4.5mm (it should be 5.0-5.5mm)

- The lip was too long compared with DIN71412 at over 1mm (it should be less than 0.7mm)

- The edges of the parts look very rounded as if they have been in acid for a long time (possibly as when they were cleaned as part of the plating process)

When 2 parts were grease tested it was found that the opening pressure which was initially 230psi and 160psi dropped to 150psi and 60psi. After a high-pressure test at 8000psi, a large drop like this could indicate that the spring may fail with repeated use.

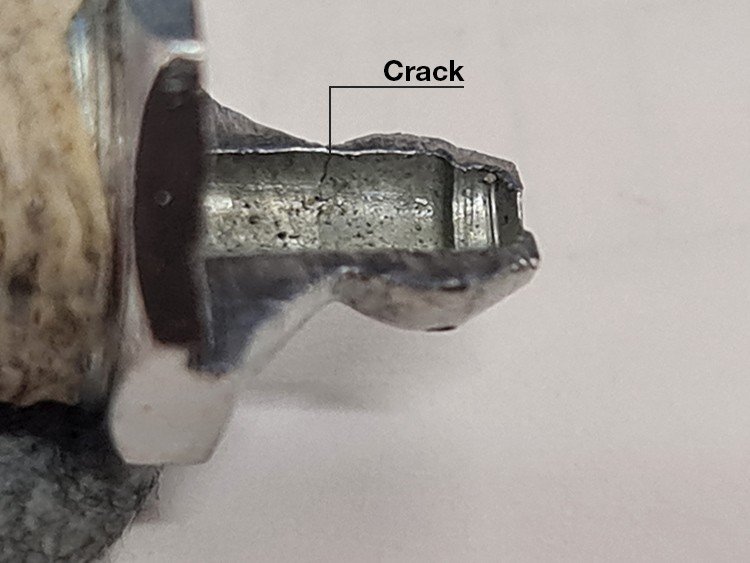

When the 2 parts were leak tested at 5000psi, one leaked all its grease past the ball. The other part leaked out of the neck! When this part was sectioned, it was found that, although the ball check was central, the internal drilling was very off centre and the neck wall was very thin and had cracked.

This failure could result in serious consequences. If the head completely snapped off during greasing at pressures of up to 8000psi, the resulting release of grease could cause serious injury.

The internal drilling was very off-centre and the neck wall was very thin and had cracked.

Three further fittings were sectioned, and the drilling was found to be badly off in 2 more of the fittings.

The finish inside some of the fittings was extremely bad, and also of note is the ball lands on these parts are very thin or non-existent